Views: 0 Author: Qingdao Flourish Industrial and Trading Co., Ltd. Publish Time: 2025-12-15 Origin: Qingdao Flourish Industrial and Trading Co., Ltd.

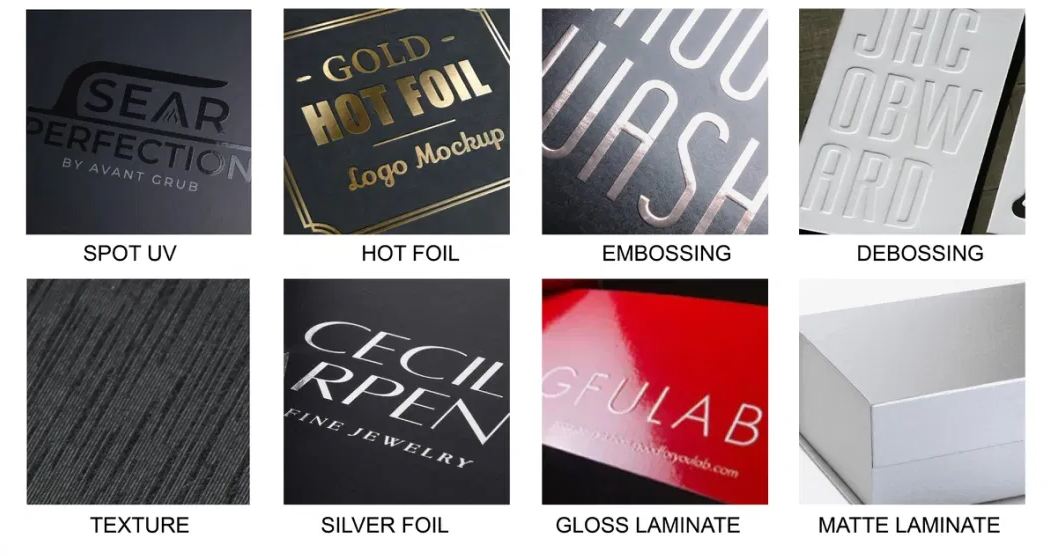

The Key Packaging Processes: Hot Stamping, Embossing, Gravure & UV Coating

✅ Hot stamping is a decorative finish using heat and pressure to transfer metallic/colored foil onto packaging (paper, cardboard, plastic). A heated die presses the foil, creating a reflective, luxurious sheen (gold, silver, matte options) that elevates logos or accents. Ideal for premium goods (cosmetics, wine, luxury boxes), it pairs well with smooth substrates for a high-end look.

✅ Embossing adds 3D texture by pressing the material between male/female dies (with heat/pressure), raising designs or patterns. Often “blind” (colorless) but usable with inks/foil, it boosts tactile appeal and visual depth, perfect for brand logos or borders on gift boxes, book covers, or food packaging. Compatible with paperboard, leather, and certain plastics.

✅ Gravure printing is a high-volume, high-quality process where images are etched into a metal cylinder. Ink fills the recesses, excess is wiped off, and the design transfers to substrates (paper, film, foil) under pressure. It delivers sharp details, vivid color reproduction, and consistent coverage—ideal for snack wrappers, beverage labels, and flexible packaging needing bold imagery.

✅ UV coating is a protective/decorative finish cured instantly with UV light. Clear or tinted, it forms a hard glossy/matte layer that enhances print vibrancy, resists scratches/smudges/moisture, and extends packaging life. Applied overall or as spot UV (highlighting logos), it creates contrast between matte/glossy textures, common for product boxes, brochures, and labels, compatible with offset/digital printing.

All four processes elevate packaging functionality and aesthetic appeal for diverse products.

We'd love to hear which printing process you think would be best suited for your product?